The boring machine was whirring and rattling away on Thursday when I stopped by to take some photos and introduce myself to the guys on site. Nick and Baz very kindly gave me a little tour of the boring machine and it’s associated trenches, and attempted to bring me up to speed with whats occurring.

I fear my countenance betrayed my barely-a-pass at GCSE combined science, as after a couple of minutes explaining about watts and aquifers, exchangers and geothermals, they clocked my baffled expression and showed me some diagrams on their phone instead!

At St George’s we’ve been talking about ground source heat pumps and boreholes for quite a long time. It might just be me who doesn’t know how they work or what’s involved with installing them, but I expect I’m not the only one. So for anyone who’d be interested to know, but daren’t ask incase they sound stupid, what follows below is a little bit of info about how ground source heat pumps work, thanks to Bruce Blaine, Nick, Baz and the wonder that is Wikipedia….

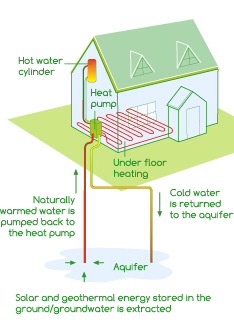

Open Loop

We’re installing an open loop system, whereby ground water is drawn from the aquifer (layers of underground rock which store water) via an extraction borehole. The water, which is always at about 12 degrees C, is used to heat the church and then returned (about 2 degrees cooler) to the aquifer via a second borehole. Both boreholes for St George’s system will be located in the north car park area, the extraction borehole is the one being dug at the moment. The advantage of an open loop is that it is unlikely to ice up in cold weather; since ground water is warm, despite being cooled by 2 degrees it will be returned to the aquifer warm, at about 10 degrees C, so it’s unlikely to freeze. …Thank goodness for that – we don’t want a heating system that freezes in cold weather!

Heating

At 12 degrees, Groundwater is warm, but its not warm enough for our purposes. The system we’re installing will take 2 degrees C off the temperature of the groundwater, and it’s these 2 degrees which need to be increased by means of a heat pump.

The plant room (currently the boiler room) will be home to the ground source heat pump and two buffer tanks which are not unlike the water cylinders we have in our homes. The heat pump takes two degrees of temperature from the groundwater to heat the water in the buffer tanks, and the heat pump then literally ‘pumps up’ the heat, the same process as refrigeration, but in reverse, to increase the temperature of the stored water in the tanks to 50 deg C. The continual flow of warm ground water and pumping up maintains the water store at 50 degrees C, and it’s this water store which in turn heats the water running through the underfloor heating pipe work.

Very Disruptive? Lots of Mess?

When I asked Nick and Baz how long the drilling would take they said usually about 2-3 weeks, then they laughed ruefully and shook their heads adding that you never really know as you can’t see what you’re drilling into; ‘Boreholes can be a….nuisance‘ (or words to that effect!) They showed me the reservoir and trenches, ready for the pipe work, and explained that they were waiting for some water ‘thickener’ to be delivered which makes the drilling easier and means it’s easier to remove debris from the reservoir. Most of the disruption and mess in the car park area will be over the next two weeks and, all being well, it will be less noisy and muddy thereafter.

(The handy diagram is from Earth Test Energy)